Diesel Fuel Filtration

With increasing operating costs (e.g., fuel usage cost, equipment downtime cost) and strict environmental legislation (e.g., GHG emissions), the mining industry faces difficult challenges when running fleets of large diesel powered engines. To ensure optimum engine performance and reliability, particulate and water contamination in diesel fuel must be controlled to acceptable (specification) limits. Standard on-board fuel filters are not designed to handle high levels of contamination. Therefore, to prevent premature plugging and frequent change-outs of on-board filters, fuel cleanliness should be controlled throughout the entire fuel supply chain.

The Impact of Particulate Contamination on Diesel Powered Engines

There are three types of engine fuel injection system failures that can be attributed to the presence of hard, particulate contamination:

- Mechanical failures from component wear and blocking component movement

- Electrical failures (typically as injector solenoid burnout) from silting around the poppet valve stem, restricting movement

- Performance failures from blocking of injector nozzles and altering injector spray patterns

Diesel Fuel Filtration Diesel Engine Fuel Injector Systems

As engine fuel injection technology has progressed, so has its sensitivity to contamination.

Electronically Controlled Unit Injectors (EUIs)

The injector nozzle openings of EUIs are 6-7 μm in diameter. These openings can become blocked or suffer erosion from particulate contamination as diesel fuel is passed through them at high pressures. Nozzle shape can be changed or spray patterns altered, adversely impacting engine performance in the form of reduced power output and poor fuel economy.

High Pressure Common Rail System (HPCR)

HPCR system technology offers improved power and fuel efficiency and lower exhaust emissions. To achieve these results, HPCR systems operate at pressures in excess of 2000 bar and have injector nozzle openings in the 2-3 μm diameter range. This requires diesel fuel 30 times cleaner than what is acceptable for standard EUIs and over 100 times cleaner than what is typically dispensed at the pump. This level of cleanliness cannot be attained with on-board filtration alone; supplementary bulk and point of filling filtration is required

Defining Acceptable Fuel Cleanliness Levels

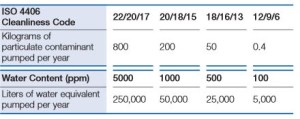

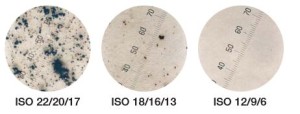

While Diesel fuel cleanliness can vary significantly along the fuel supply chain, one engine manufacturer defines typical incoming fuel cleanliness at a cleanliness level of 22/20/17 per ISO 4406.

For EUI fuel injection systems, equipment OEMs typically require a fuel cleanliness level of 18/16/13 per ISO 4406. New HPCR engines require diesel fuel cleanliness levels as low as 12/9/6 per ISO 4406.

For EUI fuel injection systems, equipment OEMs typically require a fuel cleanliness level of 18/16/13 per ISO 4406. New HPCR engines require diesel fuel cleanliness levels as low as 12/9/6 per ISO 4406.

How Dirty is it Really?

To put this into a more practical perspective, the table below shows the equivalent contaminant mass and water volume that would be pumped in one year for a large mine site using 137,000 litters of diesel fuel/day, for various fuel contamination levels.

Thus, if 0.5 % (5000 ppm) of the fuel was water, the mine would pump approximately 250,000 liters of water, equivalent to $200K* worth of fuel.

*based on 80 cents per litter

Diesel Fuel Filtration Diesel Cleanliness – a Site-Wide Investment

Diesel fuel cleanliness control must be a site-wide investment and managed with advanced particulate and water filtration technologies, from the point of delivery, through storage, right up to the dispensing nozzle.

Supplying equipment with diesel fuel at required cleanliness levels will result in a number of significant benefits, including:

- Improved diesel engine performance and reliability

- Improved diesel engine operating costs

- Reduced diesel engine maintenance costs

- Reduced vehicle downtime

- Reduced fuel consumption

- Reduced air pollution

Diesel fuel cleanliness control – from delivery, to storage, to pump, to injector…