Fuel Water Seperator

A fuel water separator is a device that works to ensure clean fuel is delivered to the engine. Fuel separators provide effective protection for engines used in automotive, industrial and marine applications. The separator removes water and solid contaminants from the fuel before it reaches the fuel pump. When the fuel contains a lot of water, it wears off the lubricants from the fuel injectors. By removing contaminants, the device prevents the engine from getting clogged up with solid material. Clean fuel enables the engine to run more efficiently. It also prevents engine failure. Diesel and marine fuel separators are amongst the most common types.

Diesel Fuel Water Separator

These are mostly made of aluminum. Diesel fuel separators are available in various sizes depending on the vehicle type. However, smaller separators need to be drained more often. Diesel fuel usually contains a higher amount of water than gasoline or other fuels. If unfiltered, this water together with dirt detracts from engine efficiency. It also makes driving a more laborious exercise. Unfiltered fuel also contributes to increased engine wear and tear.

Marine Fuel Water Separator

Plastic or aluminum is the preferred material for marine fuel water separators. These draw out water from the boat fuel which prevents water from getting into the motor. The presence of water in the motor can cause a steam explosion. This would easily damage the boat cylinders including the entire motor. The separator can be part of a primary filter or may be installed as a secondary filter. Separators drain off water in either of two ways. When the separator is part of a primary filter, water may be siphoned off by the filter. The motor gets rid of the waste water along with contaminants through this method.

When the separator is installed as a secondary filter, a siphoning mechanism is used to expel the waste water and contaminants. Water and fuel are pumped into a filter and subjected to a rapid spinning motion. The water and unwanted contaminants sink to the bottom while the fuel remains on top. This is siphoned to the fuel line. The waste water is eventually drained off as need arises. Some marine fuel water separators are designed to clean the exhaust system of the boat motor as they drain. These function in collaboration with the exhaustion system to clean it along with the fuel. It is best to replace a marine fuel water separator every year.

The Micfil Water Separators (WS) will remove free water and solid particulates from even the dirtiest, most contaminated fuel.

- Avoid fuel/water related breakdowns

- Remove solid/semi solid contaminants such as dirt, rust and sludge

- Maintain exhaust emission standard

- Extend engine rebuild period and life

How good is the quality of the fuel being used in your equipment?

How good is the quality of the fuel being used in your equipment?

If you are hiring out generators, pumps or plant, can you be sure of the condition of the fuel going into your equipment? If you are using fuel provided to you on site, can you see that it is contaminated?

Poor fuel storage, bad fuel transfer and housekeeping practices, or simple human error, can easily result in water, sand, grit, rust etc in fuel, all of these can harm your engine.

If you cannot be sure of the quality of the fuel going into your tractors, excavators, generators or pumps the engines that power them could be at risk and you could end up with expensive repairs and downtime.

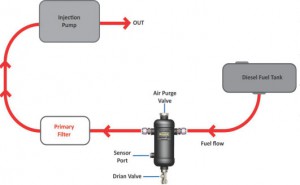

How the micfil water separator works

When the fuel enters the unit the baffles in the system immediately induce a swirling action, which causes water and solid contaminants to separate out of the fuel. The contaminants sink to the base of the unit where they are retained – the contaminants are simply drained and disposed of when the system is full. An optional sensor with buzzer can be supplied to indicate this.

When the fuel enters the unit the baffles in the system immediately induce a swirling action, which causes water and solid contaminants to separate out of the fuel. The contaminants sink to the base of the unit where they are retained – the contaminants are simply drained and disposed of when the system is full. An optional sensor with buzzer can be supplied to indicate this.