Oberdorfer Pumps has been making high-quality dependable pumps for almost every flow application. Dating back to 1890 when we manufactured our first bronze gear pump, our many loyal customers can attest that we’re an industry leader in innovation and design. From our trusted line of gear pumps to our durable CHEMSTEEL™ pumps line to our centrifugal and flexible impeller pumps, whether your needs are marine, agriculture or chemical processing, the same quality and craftsmanship goes into every single Oberdorfer™ product. Manufactured at our plant in Syracuse, New York, consistent inventory and fast delivery are an Oberdorfer™ standard and set us apart from other pump manufacturers.

Industrial

Gear pumps can be found everywhere. From car washes to paper mills and water treatment to mining, you’ll find Oberdorfer™ pumps used in nearly every industry. The Oberdorfer™ name is trusted by hundreds of leading OEMs. Our reliability and simplicity make aftermarket integration into your existing systems seamless. Oberdorfer™ is your industrial pump solution.

General Purpose

What do embalming, truck driving and aviation have in common? The answer is an Oberdorfer™ pump. We’ve been keeping the wheels of commerce turning and we have no plans to stop. Thanks to our multiline product family and more than 100 years of pumping innovation, no matter your application, there’s an Oberdorfer™ product that can be easily integrated into your system.

Marine

You want a brand you can trust on the water and Oberdorfer™ pumps deliver efficiency and peace of mind. Our centrifugal bronze pumps with Nickel Alloy Shaft are ideal in marine applications such as air conditioning, bilge and seawater recirculation. Many of the leading marine manufacturers and boat operators have come to rely on Oberdorfer™ for fuel transfer and conditioning, ballast trimming and oil transfer.

Glycol Feed

Oberdorfer™ pumps are the first choice of OEMs and engineers in glycol transfer applications. Whether used as a precursor in the production of polymers, in refrigeration or dehydration systems, these pumps are reliable and built to ensure consistent pressure and control levels across a wide variety of chemical processing applications. Oberdorfer™ should be your first choice in a system that requires a coolant pump.

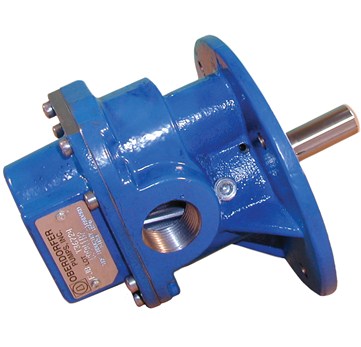

CHEMSTEEL™ pumps are designed to handle common and highly corrosive liquids that must be pumped under pressure. Manufactured to extremely precise tolerance, the CHEMSTEEL™ pump line prevents system contamination while maintaining the purity and integrity of the liquid being pumped. Its rugged, three-section construction provides ease of servicing and parts replacement. Helical gearing offers noise reduction by as much as 10db, while the tandem pumps double the output flow for a single fluid, or with isolation, handle other fluids in direct ratio to the first. Additionally, CHEMSTEEL™ pumps offer bi-directional operation for applications requiring reversing flow.

Tailored specifically for wear resistance and long life in pressurized heat transfer oil circulation service for plastic injection molding and other industries. They are industrial units designed to handle fluctuating temperature cycles pumping Therminol ®, Dowtherm ® , Paratherm ® and others at elevated temperatures to 450 °F, at pressures up to 100 psi, and at shaft speeds to 1750 RPM. Shafts are hardened steel. Gears are high-strength durable Fatigue Proof ® steel. Rugged ductile iron housings. High-grade carbon-graphite bushing style bearings and thrust plates are used. The shaft seal is a bellows style mechanical seal with fluoroelastomer elastomer bellows and o-ring and with carbon and ceramic wear faces. No stuffing box cooling necessary. Contact Factory for 550 °F option.

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are designed of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. Shaft speed and flow are directly proportional.

G & H series pumps are positive displacement helical gear pumps offering the following unique features. Both are uni-directional, i.e. rotation must be specified when pump is ordered. The reason for this requirement is that the bearing are force lubricated from the pumps pressure side to reduce seal wear and increase seal life. Rotation change and part reversal can be achieved by rotation pump over 180 degrees.

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the backpressure in the discharge line. Shaft speed and flow are directly proportional.

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. Shaft speed and flow are directly proportional.

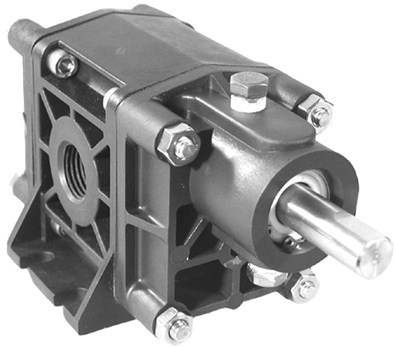

The rotary gear pump features an all bronze design and 303 stainless steel shafts with options of non-metallic gears and a variety of shaft seals. The built-in relief valve is available in two options; internal recirculation to suction side or external connection for return line to supply tank.

CHEMSTEEL™ pumps are designed to handle common and highly corrosive liquids that must be pumped under pressure. Manufactured to extremely precise tolerance, the CHEMSTEEL™ pump line prevents system contamination while maintaining the purity and integrity of the liquid being pumped. Its rugged, three-section, O-ring sealed thru-bolt construction provides ease of servicing and parts replacement. Helical gearing offers noise reduction by as much as 10db, while the tandem pumps double the output flow for a single fluid, or with isolation, handle other fluids in direct ratio to the first Additionally, CHEMSTEEL™ pumps offer bi-directional operation for applications requiring reversing flow.

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are designed of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. Shaft speed and flow are directly proportional.

Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. Shaft speed and flow are directly proportional.