PT FTS Indonesia

Tailored specifically for wear resistance and long life in pressurized heat transfer oil circulation service for plastic injection molding and other industries. They are industrial units designed to handle fluctuating temperature cycles pumping Therminol ®, Dowtherm ® , Paratherm ® and others at elevated temperatures to 450 °F, at pressures up to 100 psi, and at shaft speeds to 1750 RPM. Shafts are hardened steel. Gears are high-strength durable Fatigue Proof ® steel. Rugged ductile iron housings. High-grade carbon-graphite bushing style bearings and thrust plates are used. The shaft seal is a bellows style mechanical seal with fluoroelastomer elastomer bellows and o-ring and with carbon and ceramic wear faces. No stuffing box cooling necessary. Contact Factory for 550 °F option.

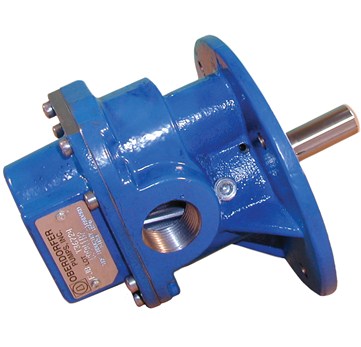

Gear Pump C990M

FEATURES

- Ductile Iron construction with hardened steel shafts

- Fatigue Proof® steel helical gears for quiet operation

- Mechanical seal

- Self lubricating carbon radial and thrust bearings

- O-ring seal for maximum leak protection

- Durable temperature-resistant paint finish

- Easy field assembly to C-face motors

- Compact dimensions

DRIVE

These close-coupled pumps mount directly to a full range of NEMA and IEC C-face motors by means of a suitable adapter bracket. The pump drive shaft is connected to the motor shaft by a flexible coupling. Complete pump and motor units are available.

LIQUIDS & TEMPERATURES

These pumps are suitable for all liquids that are compatible with bronze. Most common liquids are water, oil, and mild chemicals in the pH-range of 4 to 11. Viscous liquids require reduced shaft speeds of 1150 RPM or lower. Consult factory. Liquids containing solids, abrasives, powders or paint pigments are definitely not recommended for gear pumps. If abrasives are unavoidable, use a very low shaft speed. The recommended liquid temperature range is 32oF to 140oF for longest pump life. If more extreme temperature conditions exist, our factory should be consulted. Freezing of water-filled pumps can cause damage and must be avoided. Oils at low temperatures are very viscous requiring a lower speed or extra power.

SUCTION LIFT

Whenever possible, place the pump at an elevation below the liquid source. However since these positive displacement external gear pumps will generate 23″ HG lift, this is not a requirement. As a general rule, place the pump as close to the liquid source as possible. For a first start-up, the pump should be primed to avoid dry running. Minimum size of the suction pipe is the size of the pump inlet port. For longer suction lines (over 3 feet), the pipe size should be at least one size or two sizes larger than the pump inlet port.

ROTATION AND RELIEF VALVE

These pumps are bidirectional. The standard pump motor unit is set up for normal rotation (clockwise when viewing the pump from the shaft end). Reversing the motor rotation will reverse the “in” and “out” ports and also requires changing the relief valve location. C990RM2B1 is equipped with an integrated relief valve set up for internal bypassing. The relief valve must always be located on the discharge side of the pump. This relief valve is not intended to be a metering or flow control device. Its purpose is to function as a discharge pressure relief to guard against intermittent downstream system restrictions. Overheating can occur within 5 to 10 minutes if the discharge line is completely shut off. The relief valve is located on the discharge side of the pump. The pressure relief setting is not set at the factory. To increase pressure, turn the relief valve adjusting screw in a clockwise direction.

Order Enquiry Form

Contact form description text