PT FTS Indonesia

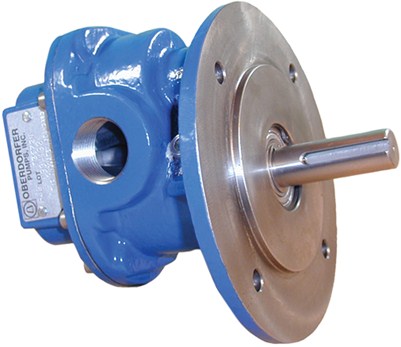

Tailored specifically for wear resistance and long life in coolant filtration service. Designed to handle a wide range of water-based and synthetic machine tool coolants at moderate temperatures to 180° F and pressures up to 100 psi and at shaft speeds to 1750 RPM. Shafts are hardened steel and gears are 416 stainless steel. Rugged ductile iron housings incorporate body/gear lubrication grooves and utilize high grade carbon-graphite bearings. The shaft seal is a bellow style mechanical seal with fluoroelastomer elastomer bellows and O-ring and with carbon and ceramic wear faces. As with all external gear rotary pumps which operate based upon close running clearances, the presence of solid particles and abrasives can lead to premature wear and damage. Use suction screens or start-up strainers when necessary.

Gear Pump C994

FEATURES

- Ductile Iron construction with steel shafts

- Stainless steel helical gears for quiet operation

- Mechanical seal

- Self lubricating carbon bearings

- O-ring seal for maximum leak protection

- Durable temperature-resistant paint finish

- Easy field assembly to C-face motors

- Compact dimensions

DRIVE

These close-coupled pumps mount directly to a full range of NEMA and IEC C-face motors by means of a suitable adapter bracket. The pump drive shaft is connected to the motor shaft by flexible coupling. Complete pump and motor units are available.

LIQUIDS & TEMPERATURES

Designed to handle a wide range of water-based and synthetic machine tool coolants at moderate temperatures to 180° F.

SUCTION LIFT

If possible, place the pump at an elevation below the liquid source. However, since these positive displacement external gear pumps will generate 23” HG lift, this is not a requirement. As a general rule, place the pump as close to the liquid source as possible. For a first start-up, the pump should be primed to avoid dry running. Minimum size of the suction pipe is the size of the pump inlet port. For longer suction lines (over 3 feet), the pipe size should be at least one or two sizes larger than the pump inlet port. These positive displacement external gear pumps will generate 23″ HG lift, a feature found to be essential for years of successful cycling. As a general rule, place the pump as close to the liquid source as possible. For a first start-up, the pump should be primed to avoid dry running. Minimum size of the suction pipe is the size of the pump inlet port. For longer suction lines (over 3 feet), the pipe size should be at least one size or two sizes larger than the pump inlet port.

Order Enquiry Form

Contact form description text