PT FTS Indonesia

Pump housings and gears are made of top quality bronze, shafts are stainless steel 303. Bearings are made of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the backpressure in the discharge line. Shaft speed and flow are directly proportional.

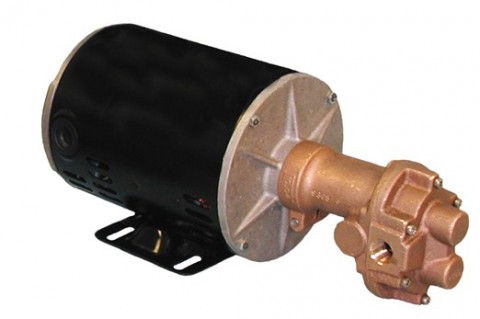

Gear Pumps Bronze ADAPTERLESS

FEATURES

- Compact design eases installation and use in limited space areas.

- No adapter needed, pump mounts directly to motor.

- Rugged Commercial AC Motors

- Automatic Thermal Overload Protection

- Open Drip Proof* – Modified NEMA 48 Frame

- Welded Rigid Base – Continuous Duty

- 115 VAC 60 HZ – Reversible

- 1/3 HP (F41) – 1/2 HP (J16)

DRIVE

Close coupled pumps are mounted directly to the electric motor. The pump drive shaft is connected to the motor shaft by a flexible coupling.

LIQUIDS & TEMPERATURES

These pumps are suitable for all liquids that are compatible with bronze. Most common liquids are water, oil, and mild chemicals in the pH-range of 4 to 11. Viscous liquids require reduced shaft speeds of 1150 RPM or lower and will require a different motor than what is listed. Consult factory. Liquids containing solids, abrasives, powders or paint pigments are definitely not recommended for gear pumps. If abrasives are unavoidable, use a very low shaft speed. See price book for the recommended liquid temperature range of lip and mechanical seals. Freezing of water-filled pumps can cause damage and must be avoided. Oils at low temperatures are very viscous requiring a lower speed or extra power.

SUCTION LIFT

As a general rule, the suction lift should be kept at an absolute minimum by placing the pump as close to the liquid source as possible. A gear pump in new condition can lift 20 feet of water in the suction line. A foot valve (preferably with built-in strainer) is recommended at the beginning of the suction line. For a first start-up, the pump should be primed to avoid dry running. Minimum size of the suction pipe is the size of the pump inlet port. For longer suction lines (over 3 feet), or for viscous liquids, the pipe size should be at least one size or two sizes larger than the pump inlet port.

Order Enquiry Form

Contact form description text