PT FTS Indonesia

G & H series pumps are positive displacement helical gear pumps offering the following unique features. Both are uni-directional, i.e. rotation must be specified when pump is ordered. The reason for this requirement is that the bearing are force lubricated from the pumps pressure side to reduce seal wear and increase seal life. Rotation change and part reversal can be achieved by rotation pump over 180 degrees.

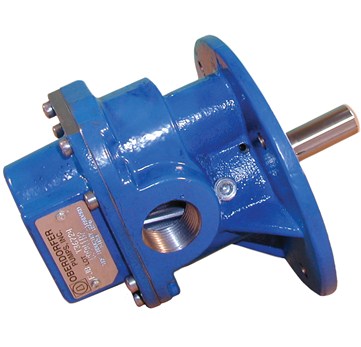

GEARIRON Pumps

FEATURES

- Capacity range 1 to 35 gallons per minute

- Viscosity range 30 to 100,000 – plus ssu

- G series shafts are ground & polished steel with pressure range from 0 to 250 psi

- H series shafts are hardened & ground to resist wear with pressure range 0 to 500 psi

- Helical gears for smooth, quiet running

- Full face thrust bearings available in bronze, carbon, cast iron and needle (for h series only)

DRIVE

Housing of close grain cast iron. Three section design insures alignment and ease of field service. All models available in pedestal type foot mount design. Sizes 05, 05, 10 & 18 available in close coupled design. G series offers optional shaft extension for pulley drive. H series offers integral outboard bearings for pulley drive support and protection against direct drive misalignment.

Bronze sleeve bearings (0 to 250 psi) are best suited for low to medium pressure for those liquids which are chemically compatible and with adequate lubricity values (viscosity) indicated in the accompanying tables. Typical liquids include lubricants, vegetable oils, mineral oils, and petroleum oils.

Iron bearings are same as described for bronze, but especially for applications where no copper can be tolerated, such as pumping animal fats and molasses silage mixtures. Iron bearings will work harden and burnish as shown on the accompanying table.

Carbon bearings are for clean liquids, including those of low viscosity (less than 100 ssu). Suitable for chemicals, solvents, water solutions, petroleum products, hydraulic oils, etc. Not suitable for abrasives as shown on accompanying tables.

Needle bearings have the highest load carrying ability covering pressure ranges from 0 to 500 psi as shown on the accompanying table. Bearings must be lubricated by liquid being pumped. Suitable for lubricating oils, mineral and vegetable oils, heat transfer oils, lubricating hydraulic oils, and petroleum lubricants. Liquids must be clean – no abrasives. NOTE: For a combination of viscosities less than 100 ssu and pressures in excess of 100 psi, carbon bearings should be used.

Optional relief valve design overcomes valve chatter and liquid surge assuring valve operates smoothly and quietly over its entire range. Pressure adjusting screw is set on the job to the desired operating pressure as per operating instructions. Pressure range from 25 psi to 300 psi. Unique design features eliminate undesirable pressure override found in most conventional relief valves. Pressure override is the extra pressure required to open the valve before it reaches the bypass flow pressure.

LIQUIDS & TEMPERATURES

Mechanical seals of Nitrile, fluoroelastomer, Polytetrafluoroethylene (PTFE), or Neoprene. Packing seals of low friction graphite, high temperature graphite or (400F) or PTFE.

Nitrile mechanical seals are suitable for oils and mild chemicals at temperature limits of -40F to 225F.

Neoprene mechanical seals are resistant to weather, ozone, gasoline and oils with temperature limits of -40F to 200F.

Fluoroelastomer mechanical seals are suitable for oils, fuels, lubricants, most mineral acids and solvents at temperature limits of -40F to 400F. PTFE mechanical seals are suitable for industrial chemicals, severe corrosives, and the more difficult solvents at temperature limits of -120F to 500F.

SUCTION LIFT

High vacuum created by the close manufacturing tolerances of the pump permit self priming at the maximum height made possible by the physical properties of the liquid being pumped. (Up to 25 ft. based on fuel oil at 70 F.)

Order Enquiry Form

Contact form description text