PT FTS Indonesia

Contaminated fuel can be incredibly damaging to diesel engines, especially those fitted with the latest generation of high pressure fuel injection systems. Water is especially troubling as it will cause serious performance and reliability problems.

The Micfil Water Separators (WS) will remove free water and solid particulates from even the dirtiest, most contaminated fuel.

- Avoid fuel/water related breakdowns

- Remove solid/semi solid contaminants such as dirt, rust and sludge

- Maintain exhaust emission standard

- Extend engine rebuild period and life

How good is the quality of the fuel being used in your equipment?

How good is the quality of the fuel being used in your equipment?

If you are hiring out generators, pumps or plant, can you be sure of the condition of the fuel going into your equipment? If you are using fuel provided to you on site, can you see that it is contaminated?

Poor fuel storage, bad fuel transfer and housekeeping practices, or simple human error, can easily result in water, sand, grit, rust etc in fuel, all of these can harm your engine.

If you cannot be sure of the quality of the fuel going into your tractors, excavators, generators or pumps the engines that power them could be at risk and you could end up with expensive repairs and downtime.

By fitting extra levels of protection on your vehicle or equipment you can reduce the risk of costly damage due to contaminated fuel.

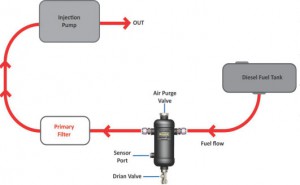

The micfil Water Separators (WS) will remove free water and solid particulates from even the dirtiest, most contaminated fuel. When fitted in conjunction with a conventional fuel water separator, they will work together to ensure that your engine is protected from harmful water and particles. The WS acts as the ‘first line of defence’ removing slugs of water and dirt, sludge and grit allowing the filter/separator to filter the fuel unhindered.

How the micfil water separator works

When the fuel enters the unit the baffles in the system immediately induce a swirling action, which causes water and solid contaminants to separate out of the fuel. The contaminants sink to the base of the unit where they are retained – the contaminants are simply drained and disposed of when the system is full. An optional sensor with buzzer can be supplied to indicate this.

When the fuel enters the unit the baffles in the system immediately induce a swirling action, which causes water and solid contaminants to separate out of the fuel. The contaminants sink to the base of the unit where they are retained – the contaminants are simply drained and disposed of when the system is full. An optional sensor with buzzer can be supplied to indicate this.

Model Options – choose your prefered micfil water separator

| Model Type | Nominal Flow | HP Guide | IN/OUT Ports | Top Port | Drain Valve Bottom Port | Width | Length | Bracket | Empty Weight |

|---|---|---|---|---|---|---|---|---|---|

| WS 100 | 1.9litres per minute | 150 HP | 14 mm | M20 Bleed Valve | 14 mm ball valve | 70 mm | 170 mm | Separate | 0.90 kg |

| WS 200 | 6 litres per minute | 250 HP | 14 mm | M20 Bleed Valve | 14 mm ball valve | 115 mm | 200 mm | Separate | 1.60 kg |

| WS 500 | 10 litres per minute | 650 HP | 14 mm | M20 Bleed Valve | 14 mm ball valve | 115 mm | 320 mm | Separate | 2.25 kg |

| WS 800 | 55 litres per minute | 850 HP | 1″ BSP | 1″ Bleed Valve | 1″ lockabke ball valve | 115 mm | 406 mm | Separate | 2.85 kg |

| WS 1000 | 150 litres per minute | 4,000 HP | 1″ BSP | 1″ Bleed Valve | 1″ lockable ball valve | 183 mm | 530 mm | Fixed to WS | 13.25 kg |

| WS 1500 | 340 litres per minute | N/A | 2″ BSP | 1″ Bleed Valve | 1″ lockable ball | 183 mm | 960 mm | Fixed to WS | 13.25 kg |

Order Enquiry Form

Contact form description text