PT FTS Indonesia

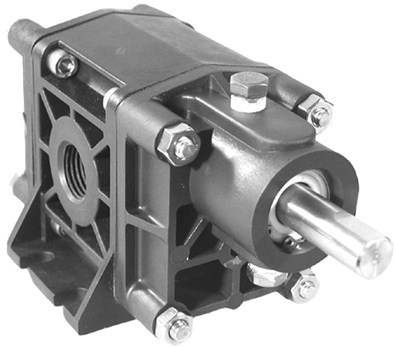

CHEMSTEEL pumps S203 NM

CHEMSTEEL™ pumps are designed to handle common and highly corrosive liquids that must be pumped under pressure. Manufactured to extremely precise tolerance, the CHEMSTEEL™ pump line prevents system contamination while maintaining the purity and integrity of the liquid being pumped. Its rugged, three-section construction provides ease of servicing and parts replacement. Helical gearing offers noise reduction by as much as 10db, while the tandem pumps double the output flow for a single fluid, or with isolation, handle other fluids in direct ratio to the first. Additionally, CHEMSTEEL™ pumps offer bi-directional operation for applications requiring reversing flow.

CHEMSTEEL pumps S203 NM

FEATURES

Gear/bearing design allows for “trimming” for optimizing the pump’s maximum flow to reach minimum turndown or to match flow to a specific OEM’s requirement.

Special materials combinations are available for specific liquids:

- Reinforced polyphenylenesulfidehousing construction.

- Gears available in metallic 316 stainless steel and Alloy C. Also in Polytetrafluoroethylene, polyphenylenesulfide and polyetheretherketone.

- Shafts are 316 stainless steel or Alloy C.

- Bearings available in carbon or Polytetrafluoroethylene.

- Full range of seal options including lip seal, packing and mechanical designs.

DRIVE

The pump is driven directly from the electric motor shaft by means of a flexible coupling. A close-coupled adapter connects the pump to the motor.

LIQUIDS & TEMPERATURES

This pump is suitable to handle clear lubricating and non-lubricating fluids at temperatures to 200F. These pumps will handle viscous fluids to 100,000 cps (462,000 SSU) at reduced shaft speeds.

SUCTION LIFT

This pump has a suction lift capability of 20 feet for a new pump. Though gear pumps are self-priming, a foot valve is recommended. If possible, wet gears with the liquid to be pumped for the first dry start. Liquid retained in the system and gear chambers serves to wet the pump on subsequent starts.

MAINTENANCE

A three-part housing provides easy disassembly and service. Full size bearings match the gear diameter, and eliminate the need for separate wear plates. TFE encapsulating silicone pump housing seals provide elastic memory to assure an effective long lasting seal and thus avoiding the re-torqueing required of pumps using pure TFE. The upper shaft configuration lends itself to in-line pump seal maintenance without the leakage of trapped chemicals from an incompletely drained pump.

To order a CHEMKIT™ parts kit, simply add a “K” to the end of the model number. A repair kit contains the following parts: seals, bearings, gears, o-rings, shafts, keys, c clips, and retaining ring.

LIFE CYCLE/COST OF OWNERSHIP

Pump design and materials selection, together provide the longest life available from a gear pump. Key attributes include:

- Gear & bearing combinations of metallic and nonmetallic wear surfaces.

- Slotted bearings to lubricate shaft and gear surfaces.

- Hydraulic porting to balance axial thrust and to reduce wear.

- Ample port sizing to reduce the likelihood of cavitation when inlet pressure is marginal.

- Effective housing seals with elastic memory prevent leakage of corrosives.

FIT

Connections are female NPT or BSPT, pump hardware is metric and close couple adapters mount to both NEMA and IEC standard motor frame sizes for worldwide acceptance.

Order Enquiry Form

Contact form description text