PT FTS Indonesia

The Blade Master ® 1500DC Series has set the industry standard for 1 ½” stationary transfer pumps for over 15 years. The 1500DC Series is engineered to outperform and outlast any other positive displacement transfer pump available, and is the most popular Blade Master® model.

Dixon Pumps 1500 DC Series

Our patented dual impeller and wiper blade technologies generate greater suction than any other positive displacement pump, while reducing repair costs and increasing the ease of maintenance by focusing the wear of the pump head components on the wiper blades rather than the actual impeller. This is also what gives the Blade Master line of pumps the ability to operate completely dry for more than 1000 hours without damaging the pump head or impellers, and causes only light wear on the wiper blades while moving product faster than other positive displacement pump designs.

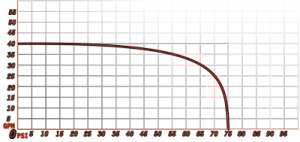

All Blade Master® pumps also feature a reversible full flow bypass, which allows the full circulation of product in the pump chamber when in bypass mode. This means that the product circulating within the pump chamber while in bypass mode is not sheared or damaged. Each bypass is built to customer specification for the bypass to activate at 25, 50, 75, or 100 PSI based on the application. Blade Master® pumps are also self-priming

The new Gen II line of Blade Master® products features all of the same standard features as the Generation I pumps, but includes expanded capabilities and a completely redesigned pump head. The Gen II is built around a new 3 lobe impeller, which reduces energy consumption, noise, and friction while increasing outflow. In addition to the redesigned impeller, each lobe now functions with three wiper blades. This allows the Gen II to produce 200% more suction and 30% more discharge than previous designs. The redesigned Gen II pump head is also available with our new Permanent Magnet Motor technology, which together form one of the safest and most efficient transfer pumps available.

1500AC Series pumps are capable of transferring in many conditions, including explosive environments, and are designed to handle applications across a range of products including:

- Diesel Fuel

- Motor Oil

- Antifreeze

- Aviation Fuels

- Gasoline

- Gear Lubes

- Chemicals

- And More

Standard Features of the 1500DC Series Include:

- Capable of up to 40 GPM

- Self-Priming

- Can operate completely dry

- Pump head, motor, and powder-coated frame are included and covered by our 2-year warranty

- TEFC and explosion proof models available

- Reversible full flow bypass protects product from shearing

Order Enquiry Form

Contact form description text