PT FTS Indonesia

Gear Pumps Cast Iron

These pumps are bidirectional. The standard pump motor unit is set up for normal rotation (clockwise when viewing the pump from the shaft end). Reversing the motor rotation will reverse the “in” and “out” ports and also requires changing the relief valve location.

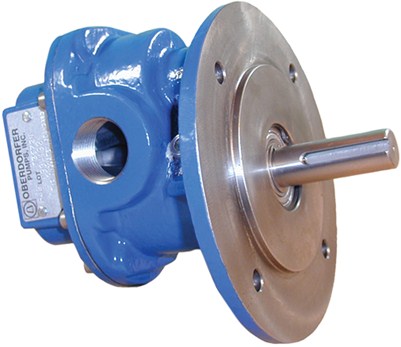

Gear Pump C994

Tailored specifically for wear resistance and long life in coolant filtration service. Designed to handle a wide range of water-based and synthetic machine tool coolants at moderate temperatures to 180° F and pressures up to 100 psi and at shaft speeds to 1750 RPM. Shafts are hardened steel and gears are 416 stainless steel. Rugged ductile iron housings incorporate body/gear lubrication grooves and utilize high grade carbon-graphite bearings. The shaft seal is a bellow style mechanical seal with fluoroelastomer elastomer bellows and O-ring and with carbon and ceramic wear faces. As with all external gear rotary pumps which operate based upon close running clearances, the presence of solid particles and abrasives can lead to premature wear and damage. Use suction screens or start-up strainers when necessary.

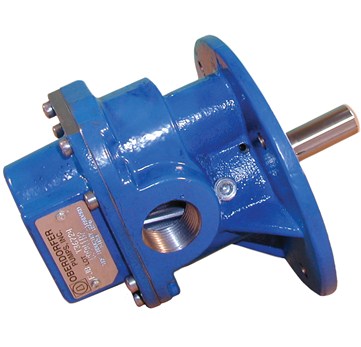

Gear Pump CB62060GRC

Drop in replacement for model GCBN3V. Can also be considered as replacement for model 4KHP9. These self-priming, positive displacement, external rotary gear carbonator pumps are ideal for a wide range of commercial, industrial, marine, and agricultural applications.

GEARIRON Pumps

G & H series pumps are positive displacement helical gear pumps offering the following unique features. Both are uni-directional, i.e. rotation must be specified when pump is ordered. The reason for this requirement is that the bearing are force lubricated from the pumps pressure side to reduce seal wear and increase seal life. Rotation change and part reversal can be achieved by rotation pump over 180 degrees.

- 1

- 2

Testimonials

“I am sending you this email to tell you how happy my customers in the Oilfield Services have been over the past two years with your CHEMSTEEL™ brand of pumps, the S21416CZ, S92316CZ and S93516CZ in particular. They are using the S214 pumps for 6GPM chemical injection, in place of the small triplex pumps they had been using for years, and the S923 pumps for 14GPM chemical injection also along with the S935 model for 22GPM for friction reducer. The larger pump is replacing PC pumps that they have been using. I am happy to say that they have told me they like the way your pumps operate and don’t have to replace parts nearly as often as they used to do with the other lines of pumps they were using. I have even been able to sell them some of your pumps for new chem-add pump trucks as well as new blender pump units. Looking forward to a long and prosperous relationship with you over the next years.”

“Oberdorfer™’s CHEMSTEEL™ line of alloy and non-metallic gear pumps has been a tremendous asset for our company. We have solved several customer applications challenges with this versatile, economical, yet rugged pump. The folks at Oberdorfer™ have made CHEMSTEEL™ pumps the most comprehensive and versatile chemical-duty gear pump available in the market. The choice of seals (or magnetic coupled), bearing materials and adapters for mounting allow for countless configurations to offer our customers. CHEMSTEEL™ is truly a winner. And will be for our company for years to come!”

“I just wanted to say thank you for the help on the sulfuric acid application from a couple of months ago and update you on the outcome. To date there has been no downtime in that area of the plant. The CHEMSTEEL™ pump has worked great. If you recall, it was a difficult application. Our customer had tried several different styles of pumps with varying degrees of success. It seemed with each pump they would solve one problem only to find another. After they got us involved and we got you involved, the pieces started to fall into place. They really like the simple, sturdy design and small footprint of the CHEMSTEEL™ pump. The added control that they have now over their process due to the range of flow has just added value to the product. We have another satisfied customer and you helped Industro live up to its motto – INDUSTRO: ‘People and things that work.’ ”