Contamination Control Strategies Turbomachinery is synonymous with highly productive equipment, high costs and high volumes of lubricant usage. For this reason, lubricant contamination control is critical for the reliable operation and long life of these machines. A good contamination control strategy not only will identify potential contaminants but also determine their source and establish methods […]

PT FTS Indonesia

There are many factors that can affect oil filtration, including the oil’s viscosity, flow and pressure of the oil system, oil type, the components to be protected and their cleanliness requirements, the conditions of the operating environment, and the physical filter (size, media, micron rating, dirt-holding capacity, bypass valve cracking pressure, etc.), as well as […]

Water and solid contaminants displace the diesel fuel lubricative coating on high precision injection components. The loss of this protection results in wear, erosion, surface pitting and eventual pressure loss. Many existing fuel filters aren’t designed to remove significant amounts of water. They are designed to do their job in a single step. This means they must be porous enough to allow […]

“There’s a company that claims to extend oil life by filtering contaminants down to 1 micron. Is there any risk of additive depletion by using such fine filtration systems? Is this type of filtration relevant to slow down the process of base number depletion/nitration in the case of gas engines?” The claim of extending oil […]

“If we use an engine oil with a high base number, can a commercial engine cleaner help remove sulfated ash from the valve seat?” The base number of an engine oil is directly linked to the oil’s reserve alkalinity and in particular the overbased detergent additives. These additives help neutralize acids produced with reactions of […]

When hydraulic oil turns from that golden honey color of new oil to a dark brown, does that mean it must be changed immediately? Is the system suffering from lost lubricating properties or gross contamination when this occurs, or is this a normal aging characteristic to be dismissed so long as the oil analysis results […]

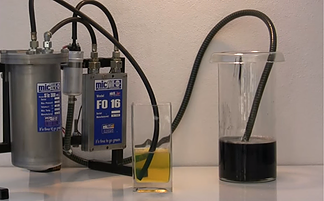

Micfil for Bulk Filtration A good solution to filter large quantities! For large industrial applications and when large quantities of fluids need to be filtered in a short time, micfil Filters and Fuel Optimizing Systems now manufactures a range of bulk fluid filtration systems, both fixed and mobile. Bulk Filtration for Refineries, oil or fuel […]

Oil contamination causes approximately 80% of all oil system failures! This contamination takes the form of insoluble materials such as metals, dust particles, sand and rubber. The smallest particles, those below 2 µm, and better known as silt, resin or oxidation deposits are often responsible for defects. Many of these contaminants influence equipment reliability and […]

Source Contaminants in Your Machines Source Contaminants control is an important part of a proactive maintenance strategy. The first step in keeping lubricants clean, cool and dry is to address the existing contaminants and measure their potential impact on the machinery and oils (failure modes). With this information, it will be easy to take the appropriate […]

PT FTS Indoensia Fuel Filtration Indonesia Q: I’ve been handling my diesel the same way for years. Why should I change now? A: With the exception of reducing sulphur content, fuel standards have not changed substantially in over a decade. Engines, however, have changed dramatically. In order for new equipment to run trouble-free, they require […]